A good partner for power engineering and heavy industry Applicable environment and advantages of hot dip galvanized cable tray

Release Time : 2025-04-05

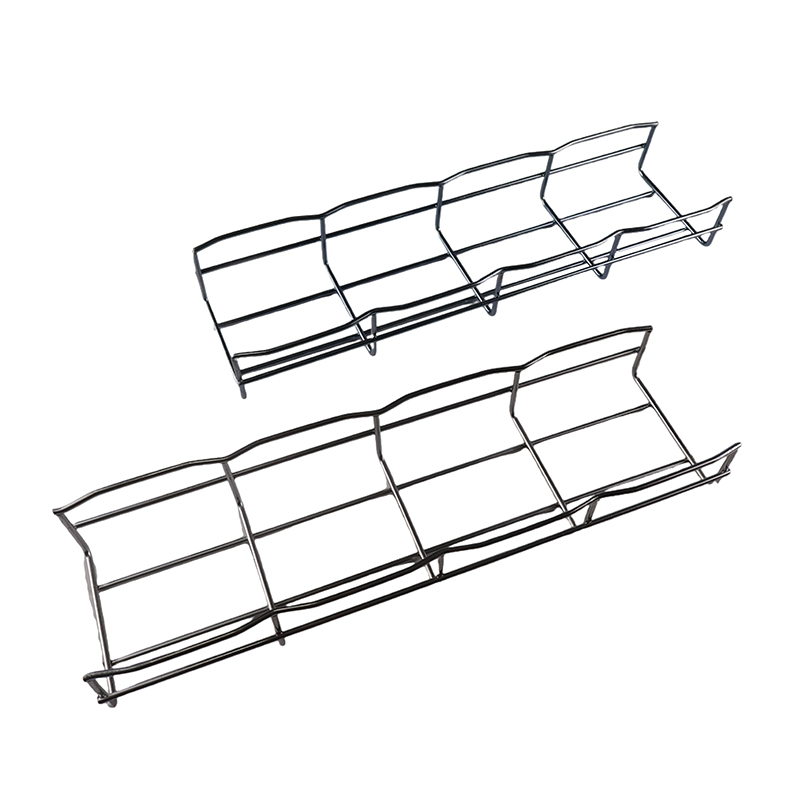

In the field of power engineering and heavy industry, the stable operation of various equipment and systems is inseparable from the support and connection of cables. The laying and management of cables have become the key links to ensure production safety and efficiency. As an important cable support equipment, hot dip galvanized cable tray has become an indispensable good partner in power engineering and heavy industry with its excellent performance and wide applicability.

Guardian in harsh environment: analysis of applicable environment

Humid environment: In power engineering and heavy industry, many places have humidity problems, such as underground tunnels, water treatment plants, chemical workshops, etc. Ordinary cable trays are prone to rust and corrosion in humid environments, resulting in a decrease in structural strength and even cable failure. Hot dip galvanized cable tray is different. Its surface is covered with a thick zinc layer, which has good anti-corrosion properties. In humid air, the zinc layer reacts with oxygen to form a dense zinc oxide protective film, which prevents moisture and oxygen from further eroding the interior of the tray. For example, in the cable laying of water treatment plants, hot dip galvanized cable trays can withstand the influence of humid environments for a long time, provide stable support for cables, and ensure the normal operation of water treatment equipment.

Acid-base environment: Heavy industrial fields such as chemical and metallurgical industries often involve the use and discharge of corrosive substances such as acids and alkalis. These substances can cause serious corrosion damage to cable trays and shorten their service life. With its excellent chemical stability, hot dip galvanized cable trays can effectively resist the erosion of acids and alkalis. The zinc layer will react chemically in an acid-base environment, but the products generated by the reaction will form a protective layer on the surface of the tray to prevent further corrosion. In the cable laying of chemical workshops, hot dip galvanized cable trays can withstand the corrosion of acid-base gases, protect cables from damage, and ensure the continuity and safety of chemical production.

Outdoor environment: Cable trays in outdoor environments face the test of natural factors such as wind, sun, rain, and snow. Ultraviolet radiation will age and brittle the material of ordinary trays, reducing their carrying capacity; rain and snow will penetrate into the interior of the tray, causing rust and corrosion. Hot dip galvanized cable tray has good weather resistance, and the zinc layer can reflect ultraviolet rays, reducing the damage of ultraviolet rays to the tray material. At the same time, the zinc layer can prevent moisture penetration and keep the inside of the tray dry. In the cable laying in outdoor substations, transmission lines and other places, hot dip galvanized cable tray can work stably for a long time, providing reliable protection for power transmission.

Excellent performance creates advantages: product advantages interpretation

Strong corrosion resistance: The hot-dip galvanizing process forms a uniform and dense zinc layer on the surface of the cable tray, which is the key to the corrosion resistance of hot dip galvanized cable tray. Compared with electroplating, hot-dip galvanizing has a thicker zinc layer and a more durable anti-corrosion effect. According to the 10-year atmospheric exposure test of the Japan Galvanizing Association, the hot-dip galvanized layer with a coating thickness of 86 microns has shown excellent durability in different environments such as heavy industry, ocean, suburbs and cities. After 13 years, 50 years, 104 years, and even 30 years of continuous verification, the hot dip galvanized process has been increasingly used in the cable tray industry and has become an indispensable means of metal corrosion protection. In power engineering and heavy industry, this strong anti-corrosion performance can greatly extend the service life of cable trays, reduce replacement frequency, and reduce maintenance costs.

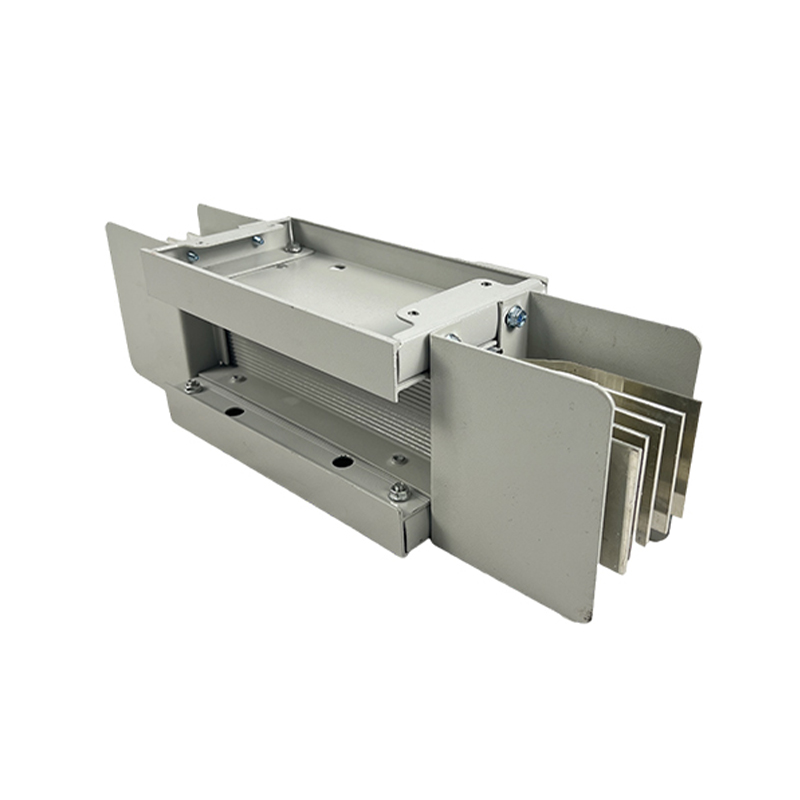

High load-bearing capacity: The hot dip galvanized cable tray has a reasonable design, uses high-strength materials and advanced manufacturing processes, and has a high load-bearing capacity. It can safely store a large number of cables and meet the laying requirements of complex cable systems in power engineering and heavy industry. In the cable tray system of large factories, the hot dip galvanized cable tray can withstand the weight of the cable and the pressure of the external environment to ensure the stable operation of the cable. At the same time, its reasonable structural design can also disperse the weight of the cable, reduce the local pressure on the tray, and improve the overall load-bearing capacity of the tray.

Long service life: Made of high-quality materials and advanced hot dip galvanizing technology, the hot dip galvanized cable tray has a very long service life. Even in harsh working environments such as high temperature, high humidity, and strong corrosion, it can maintain good performance and stability. Compared with ordinary cable trays, the service life of hot dip galvanized cable tray can be extended several times. In the long-term use process, it does not need to be replaced frequently, which reduces the equipment investment and downtime of the enterprise and improves production efficiency.

Safe and reliable: hot dip galvanized cable tray has a stable structure and is easy to install, which can meet the special needs and safety standards of power engineering and heavy industry. During the installation process, it can be used in conjunction with various brackets, hangers, etc. to form a stable cable support system. At the same time, its smooth surface will not cause wear to the cable, ensuring the safe operation of the cable. During use, hot dip galvanized cable tray can effectively prevent accidents such as cable detachment and short circuit, providing a strong guarantee for the production safety of the enterprise.

Economical and practical: Although the initial investment of hot dip galvanized cable tray may be high, it is actually an economical and practical choice considering its durability and long-term benefits. Due to its long service life and low maintenance cost, enterprises can reduce the cost of equipment replacement and repair. At the same time, the high quality and high reliability of hot dip galvanized cable tray can also improve production efficiency and reduce production losses caused by equipment failure. In the long run, it can bring significant economic benefits to enterprises.

With its excellent applicable environment and outstanding product advantages, hot dip galvanized cable tray has become an ideal choice for cable laying in the fields of power engineering and heavy industry.

Guardian in harsh environment: analysis of applicable environment

Humid environment: In power engineering and heavy industry, many places have humidity problems, such as underground tunnels, water treatment plants, chemical workshops, etc. Ordinary cable trays are prone to rust and corrosion in humid environments, resulting in a decrease in structural strength and even cable failure. Hot dip galvanized cable tray is different. Its surface is covered with a thick zinc layer, which has good anti-corrosion properties. In humid air, the zinc layer reacts with oxygen to form a dense zinc oxide protective film, which prevents moisture and oxygen from further eroding the interior of the tray. For example, in the cable laying of water treatment plants, hot dip galvanized cable trays can withstand the influence of humid environments for a long time, provide stable support for cables, and ensure the normal operation of water treatment equipment.

Acid-base environment: Heavy industrial fields such as chemical and metallurgical industries often involve the use and discharge of corrosive substances such as acids and alkalis. These substances can cause serious corrosion damage to cable trays and shorten their service life. With its excellent chemical stability, hot dip galvanized cable trays can effectively resist the erosion of acids and alkalis. The zinc layer will react chemically in an acid-base environment, but the products generated by the reaction will form a protective layer on the surface of the tray to prevent further corrosion. In the cable laying of chemical workshops, hot dip galvanized cable trays can withstand the corrosion of acid-base gases, protect cables from damage, and ensure the continuity and safety of chemical production.

Outdoor environment: Cable trays in outdoor environments face the test of natural factors such as wind, sun, rain, and snow. Ultraviolet radiation will age and brittle the material of ordinary trays, reducing their carrying capacity; rain and snow will penetrate into the interior of the tray, causing rust and corrosion. Hot dip galvanized cable tray has good weather resistance, and the zinc layer can reflect ultraviolet rays, reducing the damage of ultraviolet rays to the tray material. At the same time, the zinc layer can prevent moisture penetration and keep the inside of the tray dry. In the cable laying in outdoor substations, transmission lines and other places, hot dip galvanized cable tray can work stably for a long time, providing reliable protection for power transmission.

Excellent performance creates advantages: product advantages interpretation

Strong corrosion resistance: The hot-dip galvanizing process forms a uniform and dense zinc layer on the surface of the cable tray, which is the key to the corrosion resistance of hot dip galvanized cable tray. Compared with electroplating, hot-dip galvanizing has a thicker zinc layer and a more durable anti-corrosion effect. According to the 10-year atmospheric exposure test of the Japan Galvanizing Association, the hot-dip galvanized layer with a coating thickness of 86 microns has shown excellent durability in different environments such as heavy industry, ocean, suburbs and cities. After 13 years, 50 years, 104 years, and even 30 years of continuous verification, the hot dip galvanized process has been increasingly used in the cable tray industry and has become an indispensable means of metal corrosion protection. In power engineering and heavy industry, this strong anti-corrosion performance can greatly extend the service life of cable trays, reduce replacement frequency, and reduce maintenance costs.

High load-bearing capacity: The hot dip galvanized cable tray has a reasonable design, uses high-strength materials and advanced manufacturing processes, and has a high load-bearing capacity. It can safely store a large number of cables and meet the laying requirements of complex cable systems in power engineering and heavy industry. In the cable tray system of large factories, the hot dip galvanized cable tray can withstand the weight of the cable and the pressure of the external environment to ensure the stable operation of the cable. At the same time, its reasonable structural design can also disperse the weight of the cable, reduce the local pressure on the tray, and improve the overall load-bearing capacity of the tray.

Long service life: Made of high-quality materials and advanced hot dip galvanizing technology, the hot dip galvanized cable tray has a very long service life. Even in harsh working environments such as high temperature, high humidity, and strong corrosion, it can maintain good performance and stability. Compared with ordinary cable trays, the service life of hot dip galvanized cable tray can be extended several times. In the long-term use process, it does not need to be replaced frequently, which reduces the equipment investment and downtime of the enterprise and improves production efficiency.

Safe and reliable: hot dip galvanized cable tray has a stable structure and is easy to install, which can meet the special needs and safety standards of power engineering and heavy industry. During the installation process, it can be used in conjunction with various brackets, hangers, etc. to form a stable cable support system. At the same time, its smooth surface will not cause wear to the cable, ensuring the safe operation of the cable. During use, hot dip galvanized cable tray can effectively prevent accidents such as cable detachment and short circuit, providing a strong guarantee for the production safety of the enterprise.

Economical and practical: Although the initial investment of hot dip galvanized cable tray may be high, it is actually an economical and practical choice considering its durability and long-term benefits. Due to its long service life and low maintenance cost, enterprises can reduce the cost of equipment replacement and repair. At the same time, the high quality and high reliability of hot dip galvanized cable tray can also improve production efficiency and reduce production losses caused by equipment failure. In the long run, it can bring significant economic benefits to enterprises.

With its excellent applicable environment and outstanding product advantages, hot dip galvanized cable tray has become an ideal choice for cable laying in the fields of power engineering and heavy industry.