Why ladder type cable duct has strong corrosion resistance?

Release Time : 2024-12-25

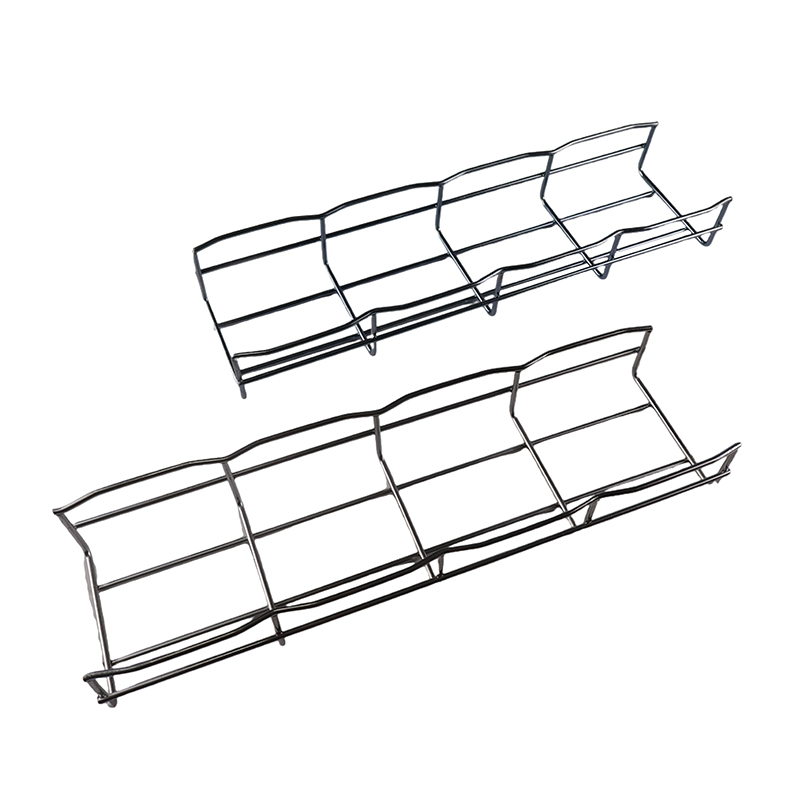

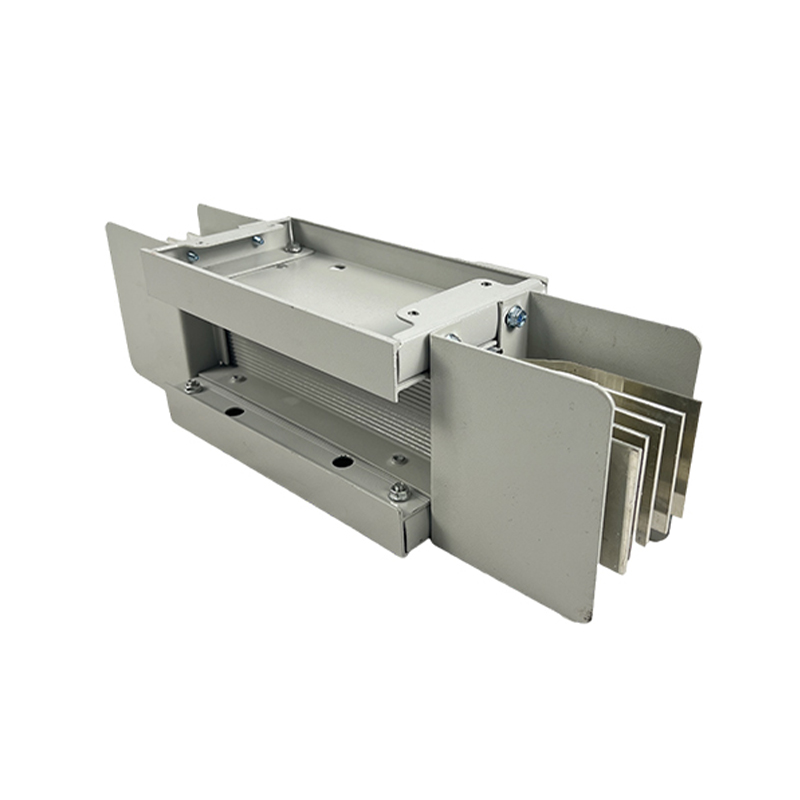

Ladder type cable duct has strong corrosion resistance, mainly due to its material selection, design and manufacturing process.

1. Material selection

High corrosion resistant materials: ladder type cable duct is usually made of highly corrosion resistant materials, such as stainless steel, galvanized steel plate, aluminum alloy or engineering plastics. These materials themselves have good corrosion resistance.

Stainless steel: such as 304 or 316 stainless steel, has excellent acid and alkali resistance and oxidation resistance.

Galvanized steel plate: The galvanized layer can effectively prevent the direct contact between the steel and the external environment and delay the corrosion process.

Aluminum alloy: Aluminum alloy has good oxidation resistance and corrosion resistance, and is light in weight.

Engineering plastics: such as polyvinyl chloride (PVC) or polypropylene (PP), have excellent chemical stability and corrosion resistance.

2. Surface treatment

Galvanized treatment: Steel cable ducts are usually hot-dip galvanized. The galvanized layer can effectively isolate the steel from the external environment and prevent oxidation and corrosion.

Anti-corrosion coating: Stainless steel cable ducts may be coated with special anti-corrosion coatings, such as epoxy or polyurethane coatings, to further enhance corrosion resistance.

Anodizing: Aluminum alloy cable ducts are anodized to form a dense aluminum oxide layer to improve corrosion resistance.

3. Structural design

Trapezoidal structure: The structural design of ladder type cable duct gives it high strength and stability, and it is not easy to deform or damage due to external forces, thereby reducing the risk of corrosion caused by structural problems.

Sealing design: Ladder type cable duct is usually designed with a sealing groove or cover to prevent moisture, dust and other corrosive substances from entering the groove and reduce internal corrosion.

4. Manufacturing process

Precision manufacturing: Advanced manufacturing processes such as cold rolling, welding and surface treatment technology are used to ensure that the surface of the cable duct is smooth, free of burrs and cracks, and reduce the starting point of corrosion.

Quality control: A strict manufacturing quality control system ensures that each product meets the technical standards and requirements for corrosion resistance.

5. Environmental adaptability

Adaptability to various environments: Ladder type cable duct is designed to adapt to various environmental conditions, including harsh environments such as humidity, acid rain, salt spray and chemical pollution, and exhibits strong corrosion resistance.

Long-term stability: After long-term use and environmental tests, ladder type cable duct can still maintain good corrosion resistance and reduce the frequency of maintenance and replacement.

6. Installation and maintenance

Easy installation: Ladder type cable duct is easy to install, reducing damage to the surface of the trough during installation and reducing the risk of corrosion.

Regular maintenance: Regularly check and maintain the cable trough, clean up the debris and accumulated water in the trough in time, keep the trough clean and dry, and extend the service life.

Through the comprehensive optimization of the above-mentioned material selection, surface treatment, structural design, manufacturing process, environmental adaptability and installation and maintenance, ladder type cable duct can show strong corrosion resistance and ensure its long-term stable operation in various harsh environments.

1. Material selection

High corrosion resistant materials: ladder type cable duct is usually made of highly corrosion resistant materials, such as stainless steel, galvanized steel plate, aluminum alloy or engineering plastics. These materials themselves have good corrosion resistance.

Stainless steel: such as 304 or 316 stainless steel, has excellent acid and alkali resistance and oxidation resistance.

Galvanized steel plate: The galvanized layer can effectively prevent the direct contact between the steel and the external environment and delay the corrosion process.

Aluminum alloy: Aluminum alloy has good oxidation resistance and corrosion resistance, and is light in weight.

Engineering plastics: such as polyvinyl chloride (PVC) or polypropylene (PP), have excellent chemical stability and corrosion resistance.

2. Surface treatment

Galvanized treatment: Steel cable ducts are usually hot-dip galvanized. The galvanized layer can effectively isolate the steel from the external environment and prevent oxidation and corrosion.

Anti-corrosion coating: Stainless steel cable ducts may be coated with special anti-corrosion coatings, such as epoxy or polyurethane coatings, to further enhance corrosion resistance.

Anodizing: Aluminum alloy cable ducts are anodized to form a dense aluminum oxide layer to improve corrosion resistance.

3. Structural design

Trapezoidal structure: The structural design of ladder type cable duct gives it high strength and stability, and it is not easy to deform or damage due to external forces, thereby reducing the risk of corrosion caused by structural problems.

Sealing design: Ladder type cable duct is usually designed with a sealing groove or cover to prevent moisture, dust and other corrosive substances from entering the groove and reduce internal corrosion.

4. Manufacturing process

Precision manufacturing: Advanced manufacturing processes such as cold rolling, welding and surface treatment technology are used to ensure that the surface of the cable duct is smooth, free of burrs and cracks, and reduce the starting point of corrosion.

Quality control: A strict manufacturing quality control system ensures that each product meets the technical standards and requirements for corrosion resistance.

5. Environmental adaptability

Adaptability to various environments: Ladder type cable duct is designed to adapt to various environmental conditions, including harsh environments such as humidity, acid rain, salt spray and chemical pollution, and exhibits strong corrosion resistance.

Long-term stability: After long-term use and environmental tests, ladder type cable duct can still maintain good corrosion resistance and reduce the frequency of maintenance and replacement.

6. Installation and maintenance

Easy installation: Ladder type cable duct is easy to install, reducing damage to the surface of the trough during installation and reducing the risk of corrosion.

Regular maintenance: Regularly check and maintain the cable trough, clean up the debris and accumulated water in the trough in time, keep the trough clean and dry, and extend the service life.

Through the comprehensive optimization of the above-mentioned material selection, surface treatment, structural design, manufacturing process, environmental adaptability and installation and maintenance, ladder type cable duct can show strong corrosion resistance and ensure its long-term stable operation in various harsh environments.