How does the aluminum electrical compact busbar lead the innovation of electrical transmission with its efficient conductivity?

Release Time : 2025-02-08

As a new type of electrical transmission medium, the aluminum electrical compact busbar is leading the innovation in the field of electrical transmission with its efficient conductivity.

1. The basis of efficient conductivity

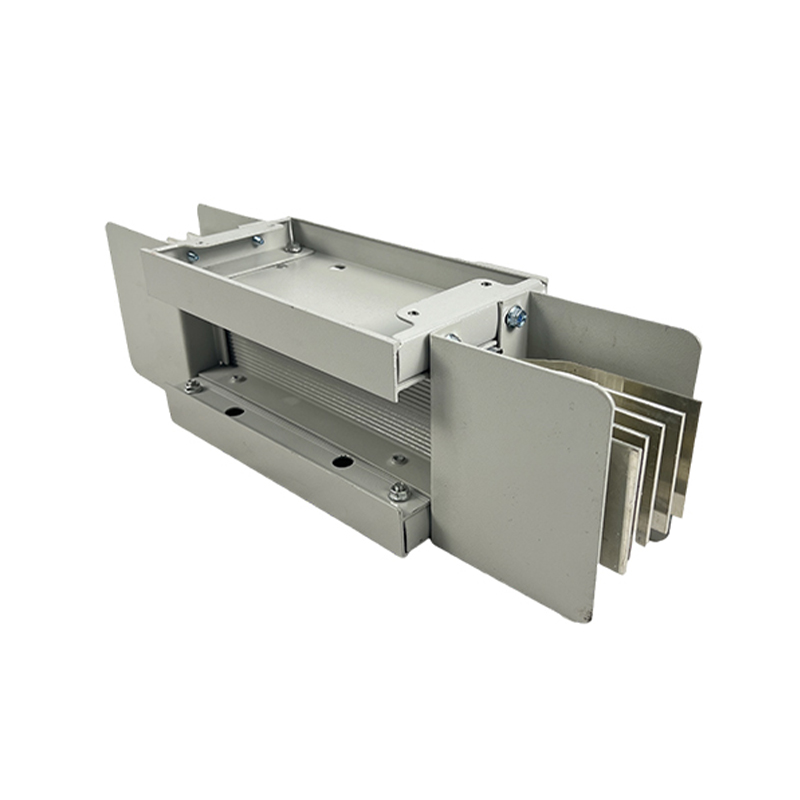

The aluminum electrical compact busbar is made of high-purity aluminum material, which has good conductivity. At 20°C, the resistivity of aluminum is 0.029 mm²/m, which is slightly higher than that of copper, but the specific gravity of aluminum is small, which is 2.7g/cm³, while copper is 8.94g/cm³. Therefore, under the same load current, although the cross-section of the aluminum busbar is larger than that of the copper busbar, the aluminum consumption is less, which makes the aluminum busbar have a higher cost-effectiveness in electrical transmission.

2. Compact design improves efficiency

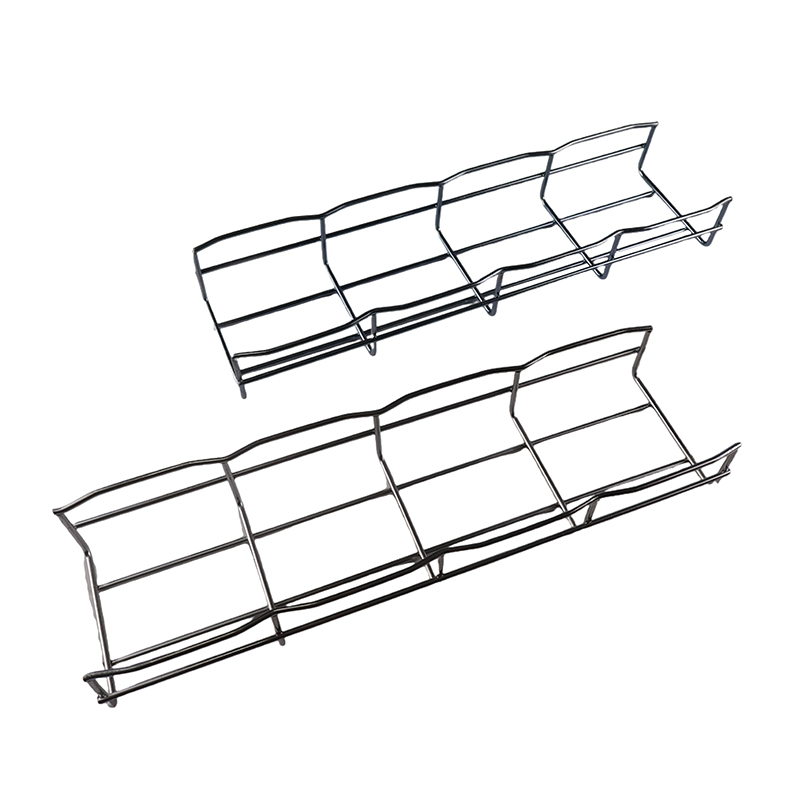

The aluminum electrical compact busbar optimizes the distribution and transmission path of the current through a compact design. Its unique tubular structure or row structure makes the current distribution more uniform and reduces the loss of current during transmission. This design not only improves the efficiency of power transmission, but also reduces the overall energy consumption of the system.

3. Application of innovative materials and processes

With the continuous innovation of materials science and manufacturing processes, the performance of aluminum electrical compact busbar has been further improved. By optimizing the material ratio and processing technology, the conductivity and mechanical properties of aluminum busbars can be improved. At the same time, the application of new surface treatment technology also enhances the corrosion resistance and service life of aluminum busbars, so that it can maintain stable operation in harsh environments.

4. Leading the innovation of electrical transmission

The efficient conductivity and compact design of aluminum electrical compact busbar give it significant advantages in the field of electrical transmission. It can not only meet the needs of modern electrical systems for efficient, stable and safe transmission, but also reduce the overall cost and maintenance cost of the system. Therefore, aluminum electrical compact busbar is gradually replacing traditional copper busbars and becoming a new favorite in the field of electrical transmission.

5. Broad application prospects

Aluminum electrical compact busbar has broad application prospects in many fields such as power systems, industrial equipment, and construction. In power systems, it can be used for power transmission between generators and transformers, as well as the connection of buses of different voltage levels in substations. In the field of industrial equipment and construction, it can also serve as the main transmission channel for electric current, ensuring the efficient distribution and use of electricity.

In summary, the aluminum electrical compact busbar is leading the innovation in the field of electrical transmission with its efficient conductive performance, compact design, and the application of innovative materials and processes.

1. The basis of efficient conductivity

The aluminum electrical compact busbar is made of high-purity aluminum material, which has good conductivity. At 20°C, the resistivity of aluminum is 0.029 mm²/m, which is slightly higher than that of copper, but the specific gravity of aluminum is small, which is 2.7g/cm³, while copper is 8.94g/cm³. Therefore, under the same load current, although the cross-section of the aluminum busbar is larger than that of the copper busbar, the aluminum consumption is less, which makes the aluminum busbar have a higher cost-effectiveness in electrical transmission.

2. Compact design improves efficiency

The aluminum electrical compact busbar optimizes the distribution and transmission path of the current through a compact design. Its unique tubular structure or row structure makes the current distribution more uniform and reduces the loss of current during transmission. This design not only improves the efficiency of power transmission, but also reduces the overall energy consumption of the system.

3. Application of innovative materials and processes

With the continuous innovation of materials science and manufacturing processes, the performance of aluminum electrical compact busbar has been further improved. By optimizing the material ratio and processing technology, the conductivity and mechanical properties of aluminum busbars can be improved. At the same time, the application of new surface treatment technology also enhances the corrosion resistance and service life of aluminum busbars, so that it can maintain stable operation in harsh environments.

4. Leading the innovation of electrical transmission

The efficient conductivity and compact design of aluminum electrical compact busbar give it significant advantages in the field of electrical transmission. It can not only meet the needs of modern electrical systems for efficient, stable and safe transmission, but also reduce the overall cost and maintenance cost of the system. Therefore, aluminum electrical compact busbar is gradually replacing traditional copper busbars and becoming a new favorite in the field of electrical transmission.

5. Broad application prospects

Aluminum electrical compact busbar has broad application prospects in many fields such as power systems, industrial equipment, and construction. In power systems, it can be used for power transmission between generators and transformers, as well as the connection of buses of different voltage levels in substations. In the field of industrial equipment and construction, it can also serve as the main transmission channel for electric current, ensuring the efficient distribution and use of electricity.

In summary, the aluminum electrical compact busbar is leading the innovation in the field of electrical transmission with its efficient conductive performance, compact design, and the application of innovative materials and processes.